Procedure

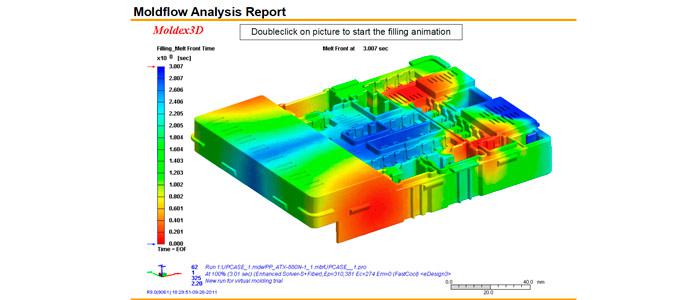

MFA

Mold flow analysis report is necessary to ensure tooling quality, specially for big or complex part, or resin with easy deformation character,through analysis, proper gate position, efficient cooling

MOREDR(DFM)

Design review for manufacturing (DFM) will be proceeded right after 3D data availability, prior to tooling design, DFM report detects all key details of tooling design and fabrication, eg. Tooling str

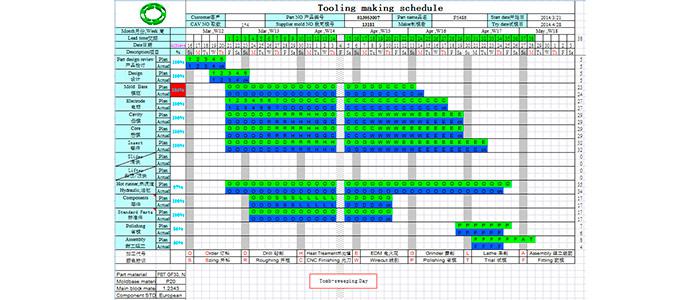

MORESchedule Planning Report

Schedule will be offered no matter it’s for product development or manufacturing. Plan VS actual status will be tracked via weekly project report which includes all status about mold base, cavity, ele

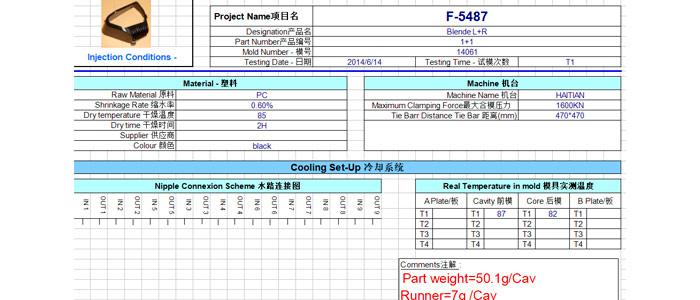

MORETesting Report & Action Plan

Testing report include information: Injection parameter; Part photos, photos with drawback; Testing movie (1-2 cycle time); Samples tracking number (Waybill); First Article Inspection report; Action p

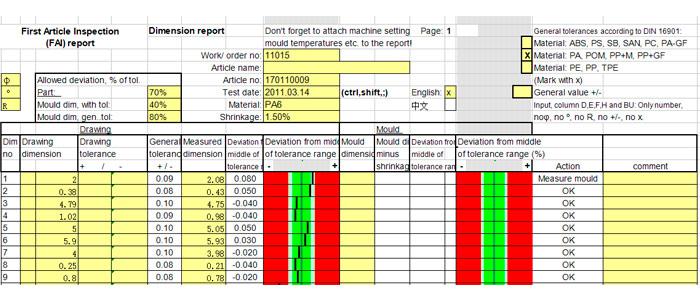

MOREFAI, CPK & PQC & FMEA

After first off tool (FOT), we provide First Article Inspection (FAI) report; When running a production we provide CPK & PQC & FMEA accordingly

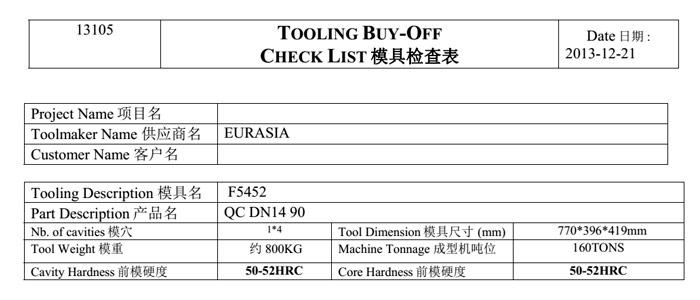

MOREMold Check List & Transfer Rep

Before mould shipment, engineering team assigned to disassemble the tooling and check tooling detail according to tooling and customer specification. Meanwhile, the following goods will be packed in

MORE